The failure of polymer and plastic materials often is caused by the inhomogeneous distribution of the used components inside the polymeric material. Also contaminations like particles, fibers or inclusions may be the reason for its failure. In case of composite materials defect layers or a layer made from the wrong material will have a negative impact on the product properties. As such defects are often extremely small they are hard or even impossible to analyze by a macroscopic measurement. However, a successful failure analysis includes the chemical analysis of the faulty region in the sample.

FT-IR microscope LUMOS II is a powerful tool for failure analysis: It allows to obtain IR-spectra anywhere on the sample with high lateral resolution and thereby to reveal the chemical composition of this particular area of the sample.

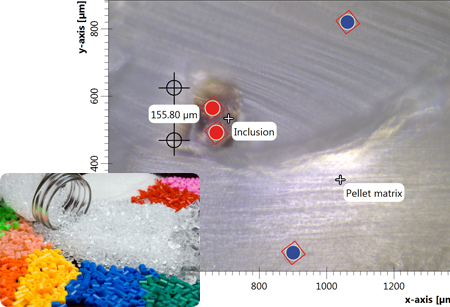

Example for the analysis of a product defect with LUMOS II: A batch of polyethylene pellets contains unwanted brown inclusions. The microscopic visual image of a polyethylene pellet with brown inclusion is shown together with the positions of the IR-analysis:

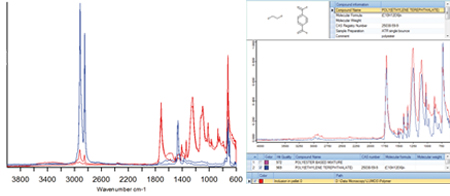

The IR-spectra show clearly different characteristics on the PE pellet matrix (blue spectra) and on the unknown inclusion (red spectra). Search in a spectral library identifies the inclusion to be a polyester (PET):

LUMOS II is a compact stand-alone system with full automation of all hardware components. The intuitive software of the LUMOS II guides the operator step by step through the process of data acquisition. At each step the user interface only provides these functions appropriate to proceed. Although the LUMOS II is designed to be operated by non-experts for routine applications, its exceptional sensitivity makes it also very suitable for high demanding applications.

| Learn more from our brochure about the features of LUMOS II. |  |

| See exciting examples about how the LUMOS II's large working distance eases sampling. |  |